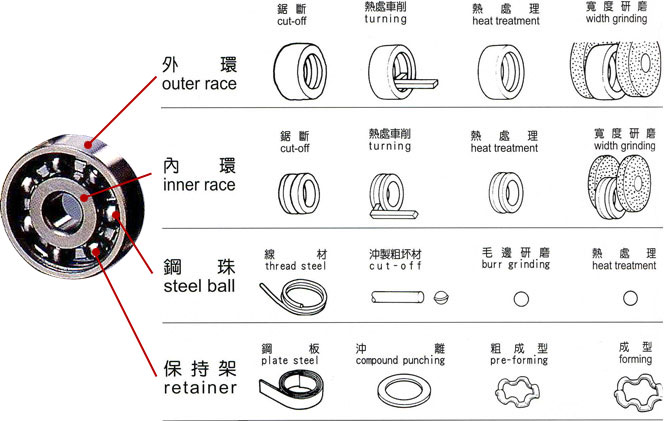

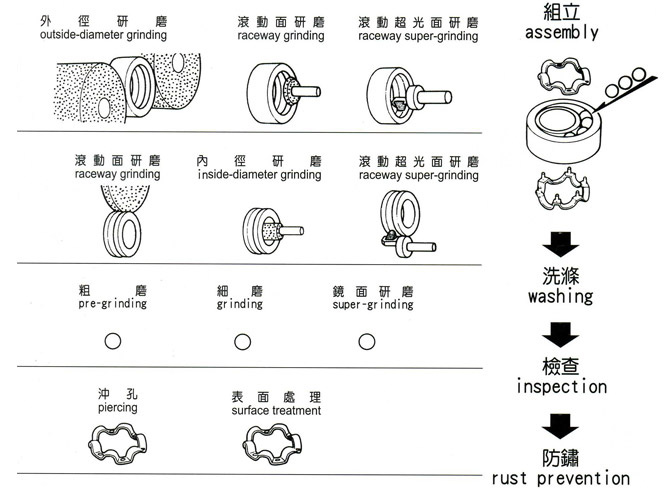

Technique

The Making of Bearing

Selection of Bearing Material

The company’s ferrule and rolling material is vacuum degassed high-carbon chromium bearing steel GCr15 manufacturing, ring hardness HRC61 ~ HRC65, steel hardness HRC62 ~ HRC66. The chemical composition of GCr15 steel is as follows:

| 元素 Element | C | Gr | Si | Mn | p | S | 0 |

| 含量 Content | 0.95 ~ 1.05 | 1.40 ~ 1.65 | 0.15 ~ 0.35 | 0.25 ~ 0.45 | <= 0.027 | <= 0.02 | <12ppm |

Selection of Bearing Clearance

The size of the bearing clearance is directly related to the bearing in the use of noise, vibration, temperature rise, service life and assembly after the mechanical movement effect. Therefore, select the appropriate assembly bearing clearance is essential, it is based on the size of the radial clearance range, from small to large divided into C2, CM, C0, C3, C4 and C5, for the specific reference please see the chart:

| Use occasions | Use example | Selection of bearing clearance |

| Strict requirements to control the noise, vibration, installation with precision, and high positioning | Equipment, instrumentation equipment, Electric motor Low noise, small motor | C2、C0 and CM |

| General load, speed, operating temperature is not high | Transmission machinery, reducer and other general machinery | C0 |

| High temperature and high speed, high service life requirements | Auto generators, engines | C3 |

| The environment temperature is high, and with inappropriate heat dissipation. | Dryer, paper machinery and so on | C3及C4 |

| High temperature and high speed, larger impact load | Vibrating sieve | C4 |

| Inside and outside the circle with interference. When the interference is large, the temperature is high, and there is no heat dissipation | Vibrating road, car rear wheel | C5 |

In actual use, adjust the selected clearance according to the corresponding situation. The ideal working clearance should be near zero clearance, so the load distribution within the bearing is at the best state, with the longest life.

Selection of DGB Bearing Clearance – Radial Table

| 軸承內徑 Bore Diameter d(mm) |

第二組(C2) Group2 |

CM組 Group CM |

基本組(0) Standart Group |

第三組(C3) Group3 |

第四組(C4) Group4 |

第五組(C5) Group5 |

|||||||

| 超過 Over |

到 To |

最小 Min |

最大 Max |

最小 Min |

最大 Max |

最小 Min |

最大 Max |

最小 Min |

最大 Max |

最小 Min |

最大 Max |

最小 Min |

最大 Max |

| 2.5 | 6 | 0 | 7 | – | – | 2 | 13 | 8 | 23 | 14 | 29 | 20 | 37 |

| 6 | 10 | 0 | 7 | – | – | 2 | 13 | 8 | 23 | 14 | 29 | 20 | 37 |

| 10 | 18 | 0 | 9 | 4 | 11 | 3 | 18 | 11 | 25 | 18 | 33 | 25 | 45 |

| 18 | 24 | 0 | 10 | 5 | 12 | 5 | 20 | 13 | 28 | 20 | 36 | 28 | 48 |

| 24 | 30 | 1 | 11 | 5 | 12 | 5 | 20 | 13 | 28 | 23 | 41 | 30 | 53 |

| 30 | 40 | 1 | 11 | 9 | 17 | 6 | 20 | 15 | 33 | 28 | 46 | 40 | 64 |

| 40 | 50 | 1 | 11 | 9 | 17 | 6 | 23 | 18 | 36 | 30 | 51 | 45 | 73 |

Selection of Bearing Clearance – Vibration and Noise Table

| Items | Chart |

|---|---|

| MAXXIMUM VIBRATION ACCELERATION OF SINGLE BEARING | Specification |

| TOLERANCE DATA FOR VIBRATION OF SINGLE BEARING |

The choice of bearing Grease Lubrication

The purpose of bearing lubrication is to reduce the internal friction which wears out the bearing, to prevent burning, to enhance bearing life, to reduce noise, to prevent foreign matter entering into the bearing, and to prevent its corrosion. For lubrication, there are two kinds, oil lubrication and grease lubrication, they are used in accordance to the specific needs and with the different working conditions and requirements, and should be applied with appropriate lubrication and grease grades.

Grease Lubrication

| Company Brand | Designation | Dropping Tem °C |

Penetration at 25 °C |

Working Tem °C |

Remarks °C |

| Shell | Alvania R2 | 185 | 265-295 | -35~120 | General perpose |

| Alvania R3 | 185 | 220-250 | -35~135 | ||

| Alvania RA | 180 | 250-275 | -25~100 | ||

| Alvania EP1 | 180 | 310-340 | -25~110 | ||

| Alvania EP2 | 185 | 265-295 | -25~110 | ||

| Darina 2 | 250 | 265-295 | -25~150 | High Tem. Service | |

| Darina EP2 | 250 | 265-295 | -25~150 | ||

| Dolium R2 | 250 | 265-295 | -35~150 | Corosion resistant | |

| Esso | Andoc C | 260 | 190-210 | -30~120 | General perpose |

| Andoc 260 | 190 | 204-260 | -40~120 | ||

| Beacon 325 | 190 | 255-280 | -54~120 | Low Tem. Service | |

| Chevron | SRI-2 | 240 | 255-280 | -30~120 | Water resistant |

| Mobil | Mobilux2 | 190 | 265-290 | -10~110 | General perpose |

| Mobilu22 | 192 | 250-274 | -40~120 | ||

| Mobilu28 | 260 | 265-295 | -55~175 | Wide range Tem. Service | |

| Mobilu48 | 260 | 240-270 | -60~170 | High Tem. Service | |

| Kluber | Isoflex LDS 18 | 190 | 255-280 | -50~110 | Low Tem. Service |

| Isoflex NBU 15 | 250 | 255-280 | -30~120 | General perpose | |

| Kyobo yushi | Multemp SRL | 185 | 225-245 | -40~145 | Low troque Service |

| Multemp pS2 | 190 | 250-275 | -50~110 | Low Tem. Service | |

| Multemp SC-A | 260 | 225-280 | 0~160 | High Tem. Service | |

| Multemp Et150 | 260 | 225-280 | -10~130 | ||

| China Hanghu | Hanghu 2 | 198 | 265-295 | -10~130 | Low noise. Service |

Sealed Bearing

The sealed bearing is divided into two types: dust cover seal and rubber seal. The rubber sealing has more variety, because of the different sealing material, the working condition of the bearing will change. For example, here are several kinds of sealing materials for reference:

| Name code | Features | Operating Temperature°C |

| Nitrile rubber NBR |

Oil, wear, heat resistance is good | -40~120 |

| fluororubber FKM |

Heat, acid and alkali and chemical, oil resistance is good | -20~200 |

| Silicone Rubber VMQ |

Heat resistance, good cold resistance, compression deformation, but poor mechanical strength | -60~230 |

| Polyacrylate rubber ACM |

Heat resistance, oil resistance better than NBR, but the water and alkali resistance is not strong | -20~150 |

Bearing Installation Instructions

Bearings should be installed in a no dust and water vapor and corrosive gases environment to ensure the bearing cleanness and installation accuracy, and to prevent foreign matter to enter into the inside of the bearing causing damage and corrosion. Installation of the use of mechanical parts should be checked according to the drawings to make sure the size of the corresponding bearing are accurate in accordance with the requirements. The surface of the bearing must be blown, cleaned with particular attention, there can not be any metal debris, blind holes, and other issues. For the interference with the bearings, it is recommended to preheat the bearing so the bearing diameter expand before the assembly of the bearing to reduce damage to the bearing. According to the user experience, the internal clearance of interference with the bearing is reduced by 55% to 75% of the amount of the interference with the bearing, the difference is mainly due to the different materials, high density material bearing clearance shrinkage significantly, and vice versa. When the bearing is mounted on the shaft or inside the housing hole, it is advised to avoid strong pressure from the outside on that the balls and ferrule rolling surfaces in the bearing, as it will damaged the bearing.

Abnormal Operation of Bearing and Corresponding Solution

| Status | Speculated reason | Corresponding Solution |

| Abnormal increase in temperature | Too much or too little grease | Verify that the appropriate amount of lubricant is injected |

| Increased load | Adjust the load, modify the bearing clearance or gap | |

| Poor installation | Improve the bearing processing, installation accuracy, and the pressure of preload | |

| Corresponding side moved or external friction | Adjust the fit or replace the bearing | |

| Big shock | Poor installation | Correct the alignment accuracy of the shaft or housing, preload adjustment |

| Foreign material intrusion | Improve the cleanness of the shaft and surface shell, improve the installation method | |

| Bearing wear out or deformation | Replace the bearing | |

| Grease leaking or change color | Too much grease or seal is not strong, outside oil and water intrusion, etc. | Adjust the amount of grease or replace the seal form, improve the bearing working environment |

| Loud noise | Bearing damage, stripping, clearance is too large | Replace the bearing |

| Foreign material intrusion | Cleaning parts, replacing the sealing device, using clean grease | |

| Loud noise | Poor installation, abnormal load | Improve installation accuracy, improve the installation, modify the bearing clearance, adjust the pre-paid and etc |

Above action is only for some common anomalies, for each specific bearing, always check the actual bearing product to find the reasons and then develop feasible solutions.

Common Damage of Bearing and Corresponding Solution

| Types | Damage phenomenon | The reason | Corresponding solution |

| Peeled off | Roller surface and rolling surface layer has fish scale looking damage | The bearing internal clearance is too small, improper or insufficient grease, axial load change, rust, poor installation | Select the appropriate bearing internal clearance, Re-select the lubrication method and grease, re-select bearing with the axial clearance, Give the bearing a comprehensive anti-rust treatment, develop reasonable accuracy |

| Outer, inner rupture | - | Large amount of interference, impact load is too large, peel or burn mating shaft expends, housing fillet is too large | Choose the right match, Set the stable load, Make sure the fillet on the mating surface is smaller than the chamfer of the bearing |

| Electric erosion | Rolling surface has the melting point due to the spark, the surface has a small pit | The humidity in the environment is large, water or rusty substances enter into the inside of the bearing | Improve the sealing device, Improve the bearing storage environment |

| Creep | Movement occurs when the collar relative to the shaft or shell axial moves | The sleeve is not tight enough, Lack of interference | Strengthen the fastening, Increase the amount of interference |

| Retainer broken | There is deformation, wear, fracture | Impact, torque is too large Improper lubrication Poor installation | Resets the load size, Choose the appropriate lubrication method, Reduce installation errors and improve installation methods |

The above is only a few common problems in the using process, there are specific circumstances which need specific analysis for the appropriate solution.